How to build a 230Vac LED light

filed underElectronics

There is varous ways to build a 230Vac LED light, from the simple and lower cost, to the most complex and higher cost (but higher reliability)Here are some examples for you :

This is the simplest way to power a LED from 230Vac, to make an indicator for example...

Pros : Very simple and very low cost.

Cons : Very poor efficiency, reliability and voltage spike resistance. No current regulation

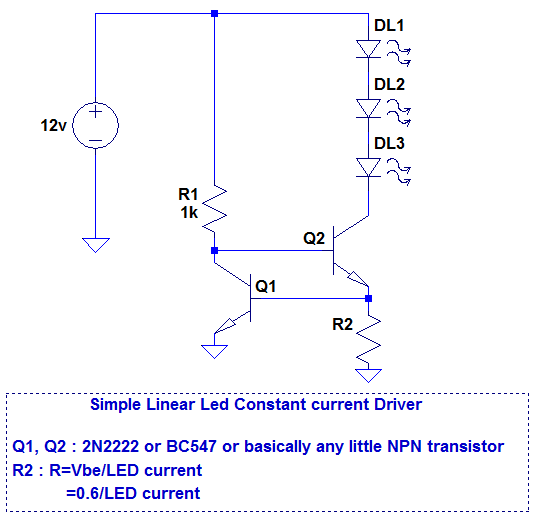

There is a more efficient way to drive Leds:

The value of C1 is easily calculated to customize your LEDs forward foltage (see the reactance formula on Google). The fuse and varistor will help to protect against high voltage spike (wich passes C1).

Pros : Still quite simple, low cost, Good efficiency

Cons : No current regulation, C1 don't block high voltage spikes (bad reliability if no protection before C1).

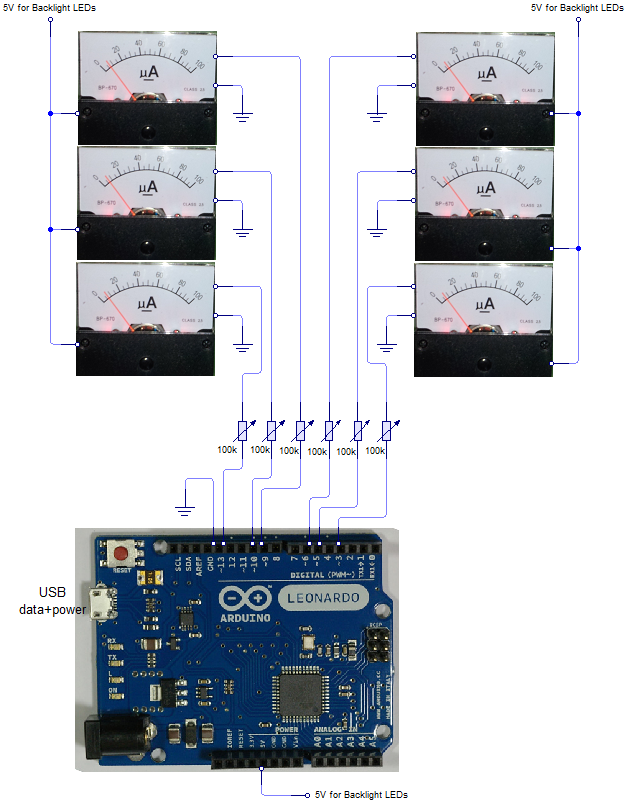

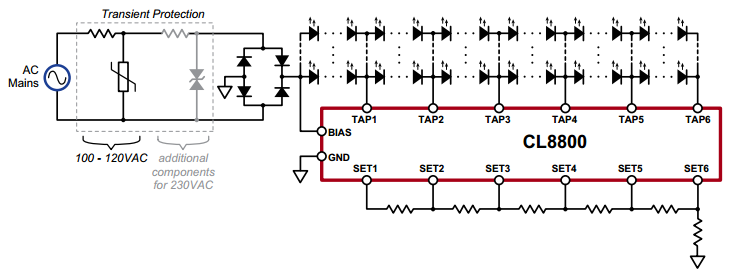

This way is one of the most common, we can find this circuit in a lot of high quality LED Bulbs (Cree, Osram, etc...).

Cons : Higher cost (transformer, mosfet...), EMI source, more failure sources (more components), more complexity (higher component count).

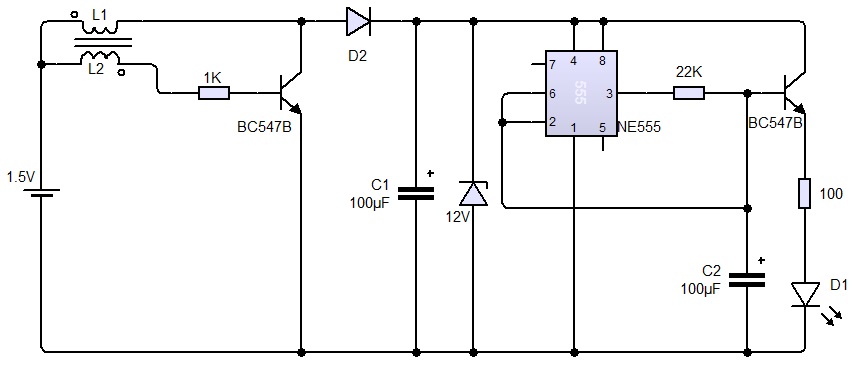

A fairly new driving mode is the folowing :

Pros : Low component count, relatively low cost, good efficiency, low profile (no big components).

Cons : Can be difficult to Dim (some LED can never be lighted), can't be flicker free (It uses the mains frequency to operate).

There are a lot of others ways to drive LEDs on 230Vac, this was just a glimpse !